Basic Knowledge of HPDC Die Casting Molds

Basic Knowledge of High Pressure Die Casting Molds

Table of Contents

- Definition of Molds

- Classification of Molds

- Structure of Die Casting Molds

- Applications of Die Casting Molds

- Application Scope and Industries of Die Casting Molds

- Quotation and Design Reference Dimensions of Die Casting Molds

- Maintenance, Usage, and Care of Die Casting Molds

Get the latest price now

What is a mold? A mold is a tool used to shape objects, which mainly realizes the processing of the shape of objects through the change of the physical state of the molding material. It is known as the “Mother of Industry”.

Molds can be divided into metal molds and non-metal molds.

Metal Molds

Metal molds include: hardware stamping dies, drawing dies, bending dies, forging dies, sand casting molds, extrusion dies, pressure casting dies, etc.

Die casting molds are installed on die casting machines and can inject molten metal into the cavity under high pressure, and maintain pressure until the metal solidifies and forms. They are mainly used for aluminum, zinc, and copper parts, and can also be used for steel parts. The structure of die casting molds is similar to that of plastic injection molds. They consist of a moving mold and a fixed mold to form the cavity, and a core is used for the hole of the casting. After the metal cools and solidifies in the cavity, the core is pulled out and the mold is separated.

Since metal is formed at the high temperature of melting, die casting molds need to be made of high-temperature resistant materials.

Non-Metal Plastic Molds

Non-metal molds include: injection molds, extrusion molds, blow molds, thermoforming molds, etc.

Plastic molds are used for plastic forming. With the development of the plastic industry, the demand for plastic molds is increasing, and their output has accounted for the first place among various types of molds. Common plastic molds include injection molds, compression molds, and extrusion molds.

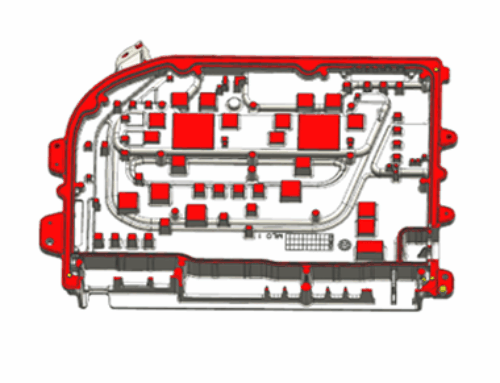

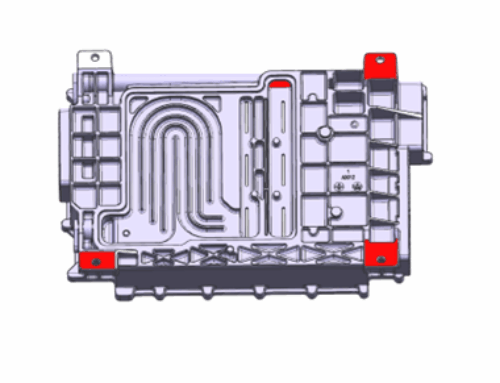

- Mold Base System

- Molding Part System

- Gating System

- Cooling or Heating System

- Venting System

- Ejection System

- Other Systems

- Forming alloy products (mainly zinc alloys, aluminum alloys, magnesium alloys, copper alloys);

- Improve the forming efficiency of castings, enable mass production, and reduce costs;

- Continuously form castings with high precision, stable dimensions, and good surface finish;

- Produce lightweight automotive parts, replacing the original steel structure with light alloys.

- Zinc, aluminum, and magnesium alloy products in the automotive industry (such as automobile underbodies, engine blocks and engine peripheral parts, automotive electronic control parts, new energy vehicle battery cases);

- Communications, computer 3C, lighting, digital video (such as filters, mobile phones, graphics card heat sinks, LED displays, street lamp heat sinks);

- Industrial engineering manufacturing, wind/thermal energy power generation devices (such as engineering machinery parts, automation parts, solar power generation parts);

- Transportation industry, aviation aircraft industry (such as power components, aircraft parts);

- Home building materials, health care (such as housing components, medical equipment, health and sports equipment).

Maintenance, Usage, and Care of Die Casting Molds

Preparation Before Production

- Before production, please check the mold drawings and mold operation instructions to be familiar with the mold structure;

- Check the mold nameplate and mold information, such as tonnage, machine table, positioning specifications, punch size, ejector rod specifications, ladle size, oil cylinder, water pipe, oil pipe, oil cylinder connector specifications, oil cylinder signal switch wiring information, etc.;

- Check the mold design parameters, such as product weight, casting pressure, punch speed, high-speed stroke, aluminum liquid temperature, mold temperature, injection time, holding time, mold cooling time, release agent ratio, etc.;

- Be familiar with the special movement mechanism and special requirements of the mold.

Mold Installation

- Select the appropriate lifting ring according to the mark on the mold, and the lifting ring must be installed correctly;

- Clean the die casting machine platen, and select the correct die casting machine shot sleeve and punch;

- The mold should be lifted balance and moved slowly into the die casting machine to ensure lifting safety;

- After the mold is positioned on the platen, ensure that the mold is vertical/horizontal;

- The mold clamps are installed correctly, and there are at least 4-8 sets of clamps on both sides of the moving and fixed molds to ensure the mold is stably installed;

- Install the mold tie rods correctly;

- Install the mold oil cylinder oil pipes and signal switches correctly;

- Slowly adjust the ejection distance of the ejector plate to a reasonable position;

- Install the water or oil pipes according to the mold drawing;

- After ensuring all installations are completed, open and close the mold slowly several times to confirm that all structural movements are smooth.

Mold Lubrication

- Add lubricating oil to the mold guide pillars;

- Spray special high-temperature oil for ejector pins on the mold ejector pins;

- For molds with potential sticking risks, a small amount of environmentally friendly graphite release paste can be applied to the cavity first;

- Debug the correct spraying position, distance, and angle of the release agent.

Production

- Before starting trial mold or production, the mold should be preheated to above 150℃, and it is recommended to use an oil temperature machine to preheat the mold;

- Before starting trial mold or production, press slowly for more than 15 mold cycles to reduce the temperature difference on the mold surface (it is recommended to slow down at 0.15-0.3M/S);

- After slow pressing, gradually set the high-speed speed, casting pressure, high/low-speed stroke, and boosting pressure according to the die casting process parameters. It is particularly reminded that all molds should use as low a punch speed and casting pressure as possible under the premise of ensuring qualified products, which helps to extend the service life of the mold (it is recommended that the maximum punch speed does not exceed 3M/S, unless in special cases);

- After the mold production is stable, the first inspection of the die castings should be carried out, and production can continue after the appearance and dimensions are qualified;

- During production, pay attention to regularly observe the mold production situation, clean the mold surface regularly, and keep the mold surface clean;

- If there is a long shutdown during production, it is recommended to repeat steps 1-3;

- If stretching or aluminum sticking is found during mold production, the spraying amount can be increased or polishing can be done.

Mold Maintenance

- After verifying that the product dimensions and functions are qualified, it is recommended to coat the main components of the mold, which helps to make mass production smoother;

- For all molds completed production, anti-rust treatment should be done on the cavity in time before being removed from the machine;

- After the mold is removed from the machine, it should be cleaned in time. If the mold needs to be repaired, it should be carried out under the guidance of professional and technical personnel;

- Regularly check the fit clearance of the mold moving parts;

- All molds delivered from the factory have undergone stress relief tempering once. Users should perform secondary tempering after about 5000 mold cycles of production, and then perform tempering once every 10000-20000 mold cycles later.