Let’s ensure the life of your mold

Appropriate mold base materials can significantly extend the mold life, ensure the stability of the production process, and reasonably control production costs.

How can we ensure the normal operation of a Die-casting factory’s production?

How can we ensure the normal operation of a Die-casting factory’s production?

aCatTech’s Guide to Characteristics and Production Applications of Materials for HPDC Mold Bases

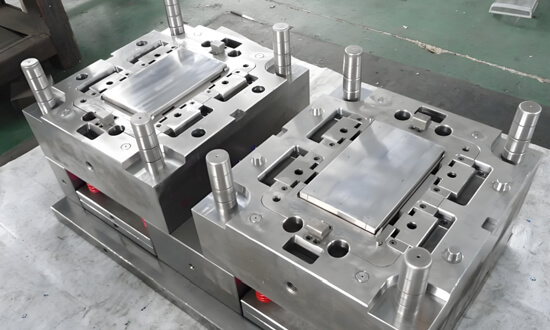

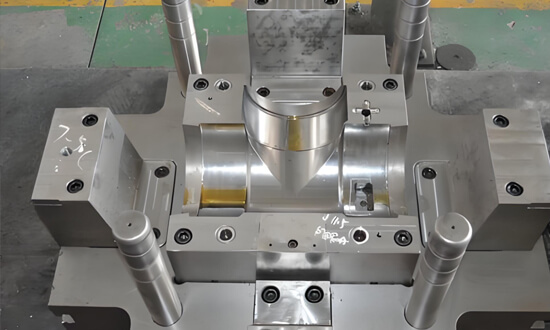

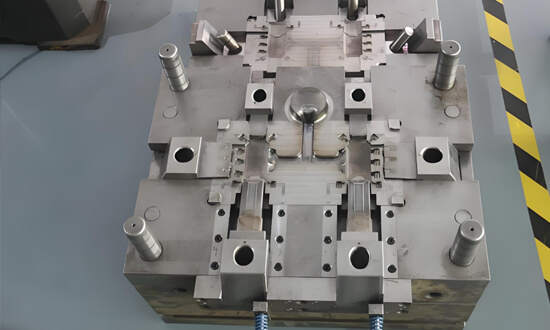

In the overall structure of high-pressure die casting molds, the mold base (including mold frames, mold feet, and other components) is the basic framework that supports the normal operation of the mold. The selection of mold base materials is directly related to the overall performance of the mold. Appropriate mold base materials can significantly extend the mold life, ensure the stability of the production process, and reasonably control production costs. Improper material selection may lead to premature mold damage, production interruptions, and a substantial increase in the company’s operating costs.

Here we focuse on three key materials widely used in high-pressure die casting mold bases: P20, S50C, and H13 ESR. It conducts in-depth analysis of their characteristics, applicable application scenarios, and matters needing attention in production applications, providing comprehensive and practical references for mold design, manufacturing, and production personnel.

Analysis of Core Material Characteristics

Die-casting Mold’s Mold Base Materials Common Problems and Solutions

Die-casting Mold’s Mold Base Materials Common Problems and Solutions

Comprehensive Comparison and Summary

Comparison Table of Core Properties of Three Materials

| Material | Hardness | Machinability | Wear Resistance | Application Scenarios |

|---|---|---|---|---|

| P20 | Pre-hardened 28-32HRC | Good cutting, drilling, and polishing performance, surface roughness can be controlled below Ra1.6μm | Has certain wear resistance, can meet the wear requirements of conventional stress-bearing components | Stress-bearing components such as mold base plates, spacers, cylinder brackets; test mold components; decorative mold pads |

| S50C | 180-230HBW | Excellent cold forming and welding performance, can be processed into complex shapes | General wear resistance, needs to be improved through surface nitriding treatment, surface hardness after nitriding reaches 500-800HV | Structural support components (spacers, feet, etc.); positioning and guiding components (positioning plates, guide rods, etc.); cross-scenario adaptation |

| H13 ESR | 44-48HRC after quenching and tempering | Relatively difficult to process, requires high tools and processes, needs to use cemented carbide tools | Excellent wear resistance, suitable for components bearing large frictional loads | Non-material flow contact wear-resistant components (lifters, wear plates, etc.) |

Future Requirements for Material Properties in High-Pressure Die Casting Molds

Future Requirements for Material Properties in High-Pressure Die Casting Molds

With the development of the high-pressure die casting industry towards high efficiency, precision, and long service life, higher requirements are put forward for the performance of mold base materials. Future mold base materials need to have a longer service life to adapt to the needs of large-scale continuous production, reduce the number of mold replacements, and improve production efficiency. At the same time, materials need to have better stability, and can maintain stable mechanical properties and dimensional accuracy during long-term use and complex working conditions to ensure the consistency of die casting quality. In addition, with the improvement of environmental protection requirements, materials should also have certain recyclability and environmental friendliness.

Steel for Mold Inserts

Only for your References

Our Business Partners