Let us take care of our molds.

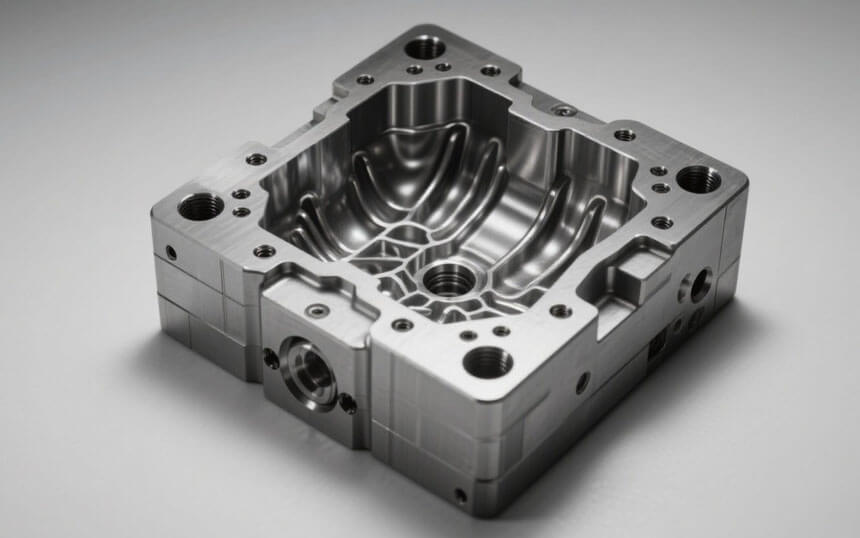

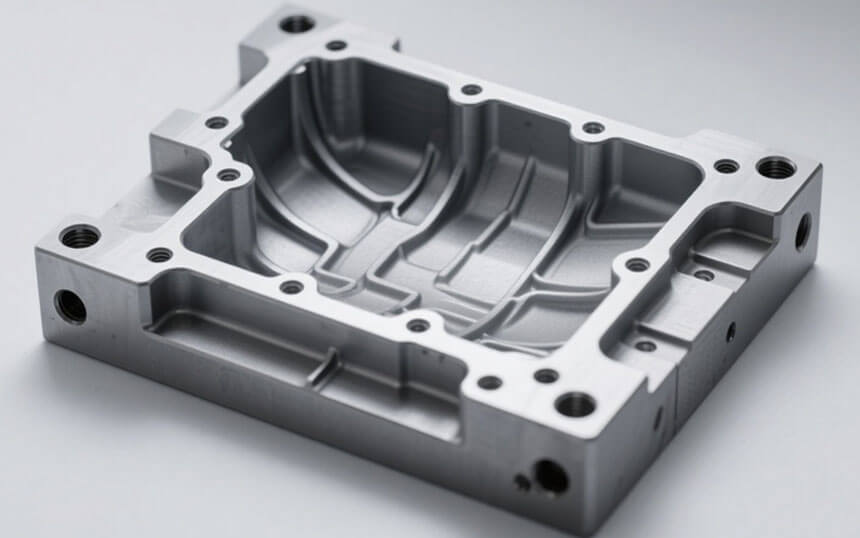

A third-party heat-treated automotive integrated die showed 4 HRC gradient (exceeding ASTM standards), leading to plastic deformation at 30,000 cycles.

Strategic cooperation system of heat treatment: deep coordination between acattech and OEM

Strategic cooperation system of heat treatment: deep coordination between acattech and OEM

The irreplaceability of original heat treatment

Material gene compatibility ASSAB DIEVAR’s patented heat treatment process (1020℃ oil cooling + 590℃ double-pass tempering) requires precise control of furnace temperature fluctuations ≤±5℃ to ensure uniform deposition of vanadium carbides, maintaining die core hardness at 46-48HRC under 600℃ conditions. When processed by third parties, equipment temperature variations often reach ±15℃, causing hardness fluctuations>3HRC and reducing high-temperature yield strength by 20% Case : The integrated die-casting mold of a car company had a hardness gradient of 4HRC (exceeding the upper limit of the national standard) due to third-party heat treatment, and plastic deformation occurred after 30,000 mold cycles. After Acattech changed to ASSAB’s original treatment, the hardness gradient was ≤1.5HRC, and the service life was increased to 180,000 mold cycles. The cryogenic revolution of 1.2344 ESR by Gleez According to acattech, Gleez has developed the -196℃×24h cryogenic process, which significantly improves thermal fatigue resistance by promoting complete transformation of martensite (conversion rate 99.5% vs. 97% in conventional process): -Thermal crack initiation cycle: 80,000 mold cycles → 220,000 mold cycles (actual measurement of a new energy vehicle battery tray project) -Reduced thermal expansion coefficient by 18%:4.8×10⁻⁶/K → 3.9×10⁻⁶/K (600℃)

Cross-border joint certification of domestic materials

| Combination of materials | Key points of original factory process | Efficiency enhancement techniques | Life (10,000 cycles) | Cost reductions |

|---|---|---|---|---|

| Fushun FS438 | Baosteel vacuum quenching (1025℃) | Laser surface texture +AlCrN coating | 15 (against 8407) | 50% |

| Baosteel BPM40 | Pre-hardened (38-42HRC) | Gradient annealing + local vanadium infiltration | 25 (over DAC55) | 40% |

Source: acattech-Baosteel Joint Technology White Paper (2025) Technical breakthrough : After acattech gradient tempering, the surface hardness of BPM40 reaches 50HRC (core 42HRC), which solves the problem of high temperature softening of traditional pre-hardened steel

Basic material science: Microscopic property control of hot work steel

Mechanism of high temperature stability Evolutionary control of carbides When DIEVAR was in service at 600℃, the Mo/V carbide size stabilized at 50-80nm (third-party treatment is easy>200nm), which is the core of its resistance to softening: -Mechanism: Vanadium carbide (VC) nailing grain boundaries and inhibiting dislocation slip -Experimental data: 600℃ yield strength of 1100MPa (30% higher than H13) Junction strengthening technology Gleitz 1.2344ESR reduced the sulfur content to 10ppm by electroslag remelting (ESR) , reducing the grain boundary segregation by 70% and the thermal cracking tendency by 40%: -The crystal boundary energy can be increased: 1.2 J/m² → 1.8 J/m² -Thermal fatigue crack propagation rate: 3.2μm/ 10,000 cycles → 1.5μm/ 10,000 cycles Materialological countermeasures for failure modes Thermal fatigue cracking ACATCH recommended the use of gradient tempering technology (cavity surface 580℃→core 520℃) to form a 200MPa compressive stress layer on the surface: -Function: offset the peak thermal stress and increase the crack initiation threshold by 300% -A case of a new energy vehicle enterprise: The maintenance interval of Moren is extended from 30,000 to 80,000 mold times Aluminum liquid erosion Laser cladding in the nozzle area CPM9V (WC-12Co alloy, HV1200): -Erosion rate: 5mg/10,000 mold times → 0.8mg/10,000 mold times -The service life of a steering joint mold is increased by 300%

Whole-process production control: acattech’s four technical barriers

Disruptive innovation in the pre-processing stage Forging pressure monitoring system Real-time analysis of metal flow direction to ensure ≥4:1 forging ratio (the qualification rate of traditional process is only 68% → acattech reaches 99%): -Technical principle: X-ray real-time imaging + deep learning to predict flow line Angle -Effect: The risk of lateral cracking is reduced by 90% Technological breakthroughs in surface enhancement

An array of micro pits with a diameter of 50μm and a depth of 10μm is processed on the surface of the gate sleeve -Aluminum flow resistance decreased by 38% -The erosion rate of the nozzle is reduced by 60% (verified by Tesla door structure project)

Advantages of detection technology: Quality firewall service simulation detection (core differentiation)

200,000 accelerated thermal cycles 72 hours of simulated ultra-long life condition (industry standard 50,000 times): -Parameters: room temperature ↔ 700℃ cycle, heating rate 100℃/s (simulated press impact) -Early warning mechanism: automatic trigger of gradient backfire compensation when crack risk is found Aluminum liquid flow field inversion system Reconstruction of the flow velocity field at the gate by computational fluid dynamics (CFD): -Case: The service life of the AlCrN coating area in the gearbox mold pre-increasing area is 220,000 times instead of 120,000 times -Precision: flow rate prediction error <0.5m/s

Steel for Mold Inserts

Only for your References

Our Business Partners