HPDC Die Casting- Basic Principles

Basic Principles of Die Casting

Table of Contents

- Basic Principles and Characteristics of Die Casting

- Common Fluid Principles and Applications

- Overview of Liquid Metal Filling Theory

- Flow State and Characteristics of Liquid Metal

Die Casting Process Cycle

- Semi-automatic die casting cycle: Clean the mold → Spray → Place inserts → Close the mold → Pour material → Inject → Cool and solidify → Open the mold → Eject → Take the part

Automatic die casting cycle: (Same steps as semi-automatic)

Conditions Related to Die Casting Production

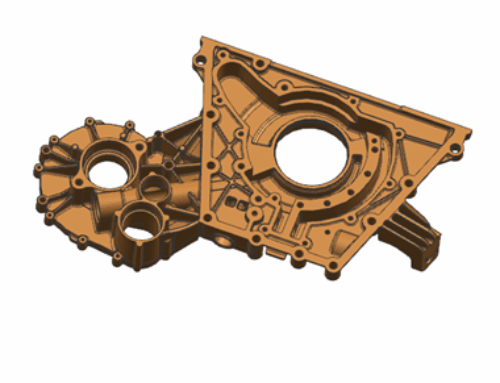

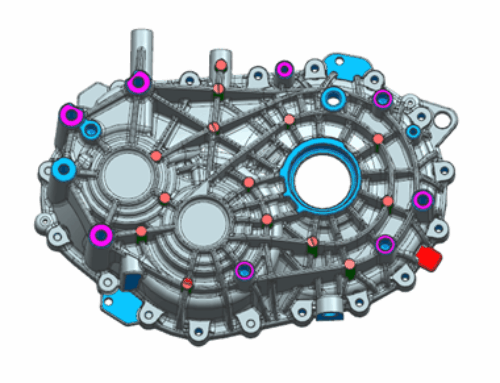

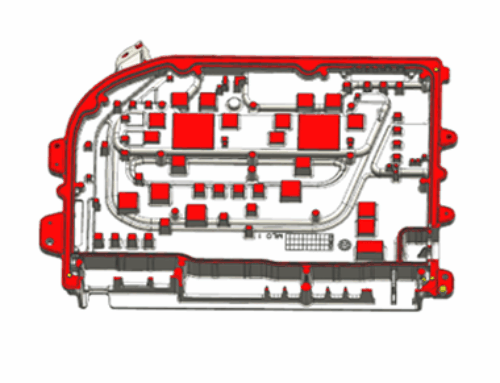

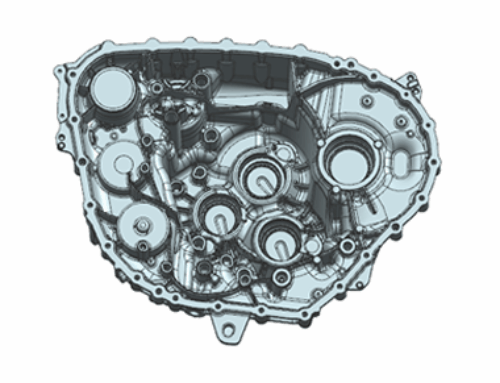

- Die casting design: Requirements (performance, appearance); Structure (fillets, draft angles, wall thickness, holes); Gating system design

- Die casting machine: Clamping, injection, ejection, feeding (pressure, speed, cycle actions); Maintain precision; Capability requirements (preheating, cooling)

- Die casting operation: Keep in normal state; Coating (type, spray amount); Die casting cycle; Mold temperature

- Die casting process: Specific pressure, filling speed, filling time; Process parameters

- Mold: Material and heat treatment; Machining accuracy; Design; Maintenance

- Alloy material and melting: Furnace charge ratio; Alloy composition; Flux usage; Temperature control; Cleanliness (gas, hard spots, foreign matter); Ratio of return material

- Die caster: Safe operation; Professional knowledge; Proficiency; Dedication; Physical strength

Application of Pascal’s Principle

Ap — Punch cross-sectional area;

Ph — Die casting machine accumulator pressure;

Ah — Injection cylinder cross-sectional area;

Injection Pressures for Various Alloys

| Alloy | Injection Pressure / MPa |

|---|---|

| Zinc alloy | 20~30 |

| Aluminum alloy | 30~80 |

| Magnesium alloy | 30~70 |

| Copper alloy | 50~80 |

Gate Speed Based on Wall Thickness

| Wall Thickness (mm) | Gate Speed (m/s) |

|---|---|

| -0.8 | 46-55 |

| 1.3-1.5 | 43-52 |

| 1.7-2.3 | 40-49 |

| 2.4-2.8 | 37-46 |

| 2.9-3.8 | 34-43 |

| 4.6-5.1 | 32-40 |

| 6.1 | 28-35 |