7 Secrets of Die Cast Tooling: How to Master Aluminium Alloy Die Casting

Why Does 22% of Die Casting Fail? The Hidden Risks

What Makes Automotive Die Casting a High-Stakes Game?

The automotive industry runs on precision. A single misaligned part can compromise safety, while delays in production can cost manufacturers millions. Aluminium alloy die casting has become a go-to solution, offering parts that reduce vehicle weight by up to 30% (Automotive Manufacturing Solutions, 2024)—a critical factor for fuel efficiency and electric vehicle range. But here’s the catch: 22% of die casting projects fail their first quality inspection (Global Casting Trends, 2024). Why?

The answer lies in the delicate balance between speed and perfection. Molten aluminium, heated to 660°C, is injected into dies at pressures between 1,000 and 10,000 PSI. Even a tiny flaw in the die—like a poorly placed vent or a weak steel section—can lead to porous castings, dimensional errors, or even tooling breakdowns. For example, a leading EV manufacturer recently reported losing $500,000 due to a single defective die that produced 2,000 faulty battery enclosures. The stakes couldn’t be higher.

Can Efficiency and Complexity Coexist in Die Casting?

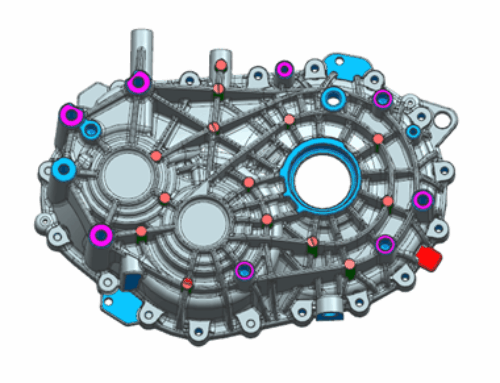

Die casting is celebrated for its speed: simple parts can roll off the line at 1,000 units per hour (Die Casting Engineer, 2023). But complexity often grinds this efficiency to a halt. Consider a transmission case with 17 internal channels: designing a die to handle such intricacy requires expertise in fluid dynamics, thermal management, and material science. Without it, manufacturers face a paradox: faster production leads to more defects, while slower production erodes cost savings.

This tension is why so many projects struggle. A survey of 500 automotive suppliers found that 68% cited “tooling complexity” as their biggest challenge (Automotive Supply Chain Report, 2024). The solution? It starts with understanding die cast tooling—not just as a component, but as the foundation of successful casting.

What Are the Pros and Cons of Aluminium Alloy Die Casting?

“Why do engineers keep choosing aluminium alloy die casting? Let’s break down the top 5 benefits:

- Tight Tolerances: For small parts, die casting achieves tolerances as tight as ±0.05mm (ISO 17082:2015). This means parts like fuel injector housings fit together without costly secondary machining.

- Superior Surface Finish: With Ra values between 1.6–3.2μm, die cast parts require minimal polishing—ideal for visible components like door handles.

- Design Freedom: Thin walls (0.75mm), undercuts, and complex internal features are possible. This is a game-changer for electric vehicle battery trays, which need to be lightweight yet structurally strong.

- Material Efficiency: Only 5–8% of raw material goes to waste, compared to 20% in traditional machining (Sustainable Manufacturing Report, 2024). For large-scale production, this translates to massive cost savings.

- Speed to Market: From design to production, die casting cuts lead times by 40% compared to forging (Manufacturing Technology Insights, 2024). This is crucial in the fast-paced automotive industry.“

4 Hidden Disadvantages You Need to Know

Die casting isn’t without its flaws. Here are the risks that often catch manufacturers off guard:

- High Tooling Costs: A production-grade die for automotive parts can cost

200,000. For small batches (fewer than 10,000 units), this makes die casting economically unfeasible.

- Porosity Issues: Rapid cooling traps air bubbles in the metal, creating pores. These weaken parts under stress— a critical problem for safety components like steering knuckles.

- Temperature Limits: Aluminium alloys like ADC12 and A380 start to soften above 200°C, ruling them out for high-heat applications like engine exhaust manifolds.

- Size Restrictions: Most die casting machines can’t handle parts over 10kg. This limits their use for large structural components like truck frames.

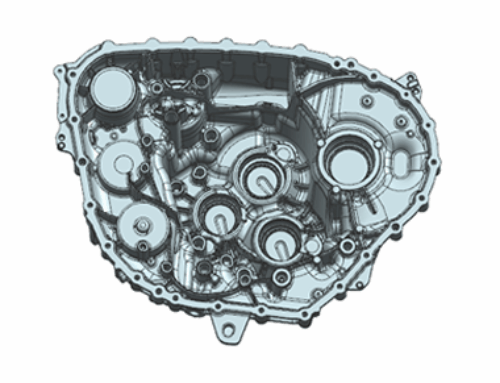

How Does Die Cast Tooling Make or Break Your Project?

The die is the unsung hero of die casting. A well-designed die can turn challenges into opportunities, while a poorly made one can derail even the best-laid plans. Let’s explore what makes a die successful:

3 Key Elements of Die Design

- Steel Selection: H13 tool steel, heat-treated to 48–52 HRC, is the gold standard. It resists wear even after 100,000+ cycles (Tooling Material Handbook, 2023) and conducts heat evenly to prevent warping.

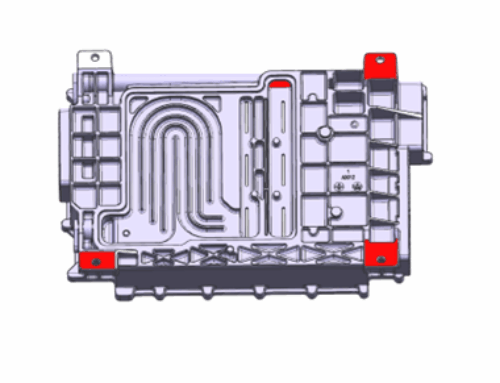

- Cooling Systems: Strategic coolant channels reduce cycle times by 30% by removing heat faster. For example, a die with optimized cooling can produce 500 more parts per day than a poorly cooled one.

- Runner and Gate Design: These pathways control how molten metal flows into the die. A well-designed runner system reduces turbulence, cutting oxide inclusions by 40% (Casting Process Simulation Studies, 2024).

5 Common Tooling Mistakes (and How to Avoid Them)

- Ignoring Venting: Trapped gas causes 60% of porosity defects (Casting Defect Analysis, 2024). Solution: Use CFD modeling to place vents where gas accumulates most.

- Choosing the Wrong Steel: Low-grade steel wears out 3x faster. Always verify heat treatment certificates to ensure H13 steel meets hardness standards.

- Poor Alignment: Misaligned die halves create flash (excess metal) and dimensional errors. Fix: Use CMM (Coordinate Measuring Machine) inspection to ensure ±0.01mm alignment.

- Inadequate Coating: Molten aluminium erodes die surfaces over time. Applying a boron nitride coating reduces wear by 50% (Die Maintenance Guide, 2023).

- Overlooking Maintenance: A die that’s not cleaned or lubricated regularly will fail 2x sooner. Schedule weekly inspections to check for cracks and wear.

How Can aCatTech Turn Die Casting Challenges Into Wins?

At aCatTech, we don’t just make dies—we solve problems. Our dual certifications (ISO 9001:2015 and IATF 16949:2016) are more than just paperwork; they’re proof of our commitment to quality. Here’s how we deliver:

- One-Stop Shop: From die design (using AutoCAD and Moldflow simulation) to casting production on 500T–4500T cold-chamber machines, we handle every step. This eliminates communication gaps between tooling and casting teams.

- Rigorous Testing: Every die undergoes 10 quality checks, including helium leak tests for cooling channels and hardness testing. We reject 3% of dies during production to ensure only the best reach our clients.

- Material Traceability: Our aluminium alloys (A380, A360, ADC12) come with full certification, so you know exactly what’s in your parts. We even provide tensile strength and elongation reports for every batch.

Ways We Solve Your Toughest Die Casting Problems

Small Batches? We Have a Cost-Effective Solution

High tooling costs shouldn’t stop small-batch production. Our rapid prototyping dies, made from pre-hardened steel, cost 60% less than production dies and deliver 5,000–10,000 parts. Perfect for testing new designs before scaling up.

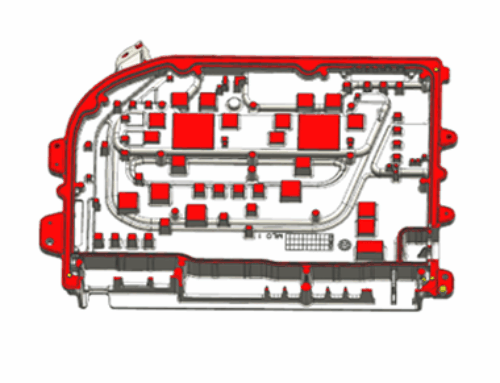

Porosity Ruining Your Parts? Try Our Vacuum Casting

We use vacuum-assisted die casting to remove 70% of trapped gas (ASTM E505 compliant). A recent client in the EV sector saw their defect rate drop from 8% to 0.3% after switching to our vacuum process for battery enclosures.

Need Complex Geometries? Our 5-Axis CNC Machines Deliver

Traditional dies struggle with undercuts and multi-directional features. Our 5-axis CNC machines carve dies with 30% more complexity, enabling parts like multi-port fuel rails that were once thought impossible to die cast.

Want Longer Die Life? Our Modular Design Saves the Day

High-wear areas (like gates) can be replaced as inserts, extending die life by 20% and reducing downtime. A tier 1 automotive supplier recently saved $120,000 by replacing inserts instead of buying a new die.

5 Common Tooling Mistakes (and How to Avoid Them)

- Ignoring Venting: Trapped gas causes 60% of porosity defects (Casting Defect Analysis, 2024). Solution: Use CFD modeling to place vents where gas accumulates most.

- Choosing the Wrong Steel: Low-grade steel wears out 3x faster. Always verify heat treatment certificates to ensure H13 steel meets hardness standards.

- Poor Alignment: Misaligned die halves create flash (excess metal) and dimensional errors. Fix: Use CMM (Coordinate Measuring Machine) inspection to ensure ±0.01mm alignment.

- Inadequate Coating: Molten aluminium erodes die surfaces over time. Applying a boron nitride coating reduces wear by 50% (Die Maintenance Guide, 2023).

- Overlooking Maintenance: A die that’s not cleaned or lubricated regularly will fail 2x sooner. Schedule weekly inspections to check for cracks and wear.

Case Study: How We Fixed a Tier 1 Supplier’s 5,000-Cycle Die Failure

A major automotive supplier was facing a crisis: their transmission case die kept failing after just 5,000 cycles, costing $30,000 in rework each time. They turned to aCatTech for help.

Step 1: Root Cause Analysis

Our engineers used thermal imaging to find hot spots in the die. The cooling channels were poorly placed, causing uneven solidification and cracking.

Step 2: Redesign the Cooling System

We added baffle-style cooling channels to extract heat 40% faster. This stabilized the die temperature at 220°C, preventing thermal stress.

Step 3: Upgrade the Steel

We switched to premium H13 steel with vacuum quenching, improving hardness consistency. This eliminated stress fractures.

Result: The die now lasts 50,000 cycles—10x longer than before. The client saved $270,000 in 12 months and reduced production downtime by 90%.