Main Products and Annual Output

Main Equipment Listing

| Equipment | Sets | Equipment | Sets | Equipment | Sets |

|---|---|---|---|---|---|

| Die-casting Machine | 14 | CNC Drill & Tap Machine | 18 | Grinding Machine | 5 |

| Mold Temperature Controller | 5 | Tapping Machine | 10 | EDM | 5 |

| CNC Milling Machine | 18 | Drilling Machine | 10 | Multi-spindle Drilling | 3 |

| Coating Thickness Gauge | X-ray | Rockwell Hardness Tester | CMM | Polishing Station | Stamping Press |

About aCatTech

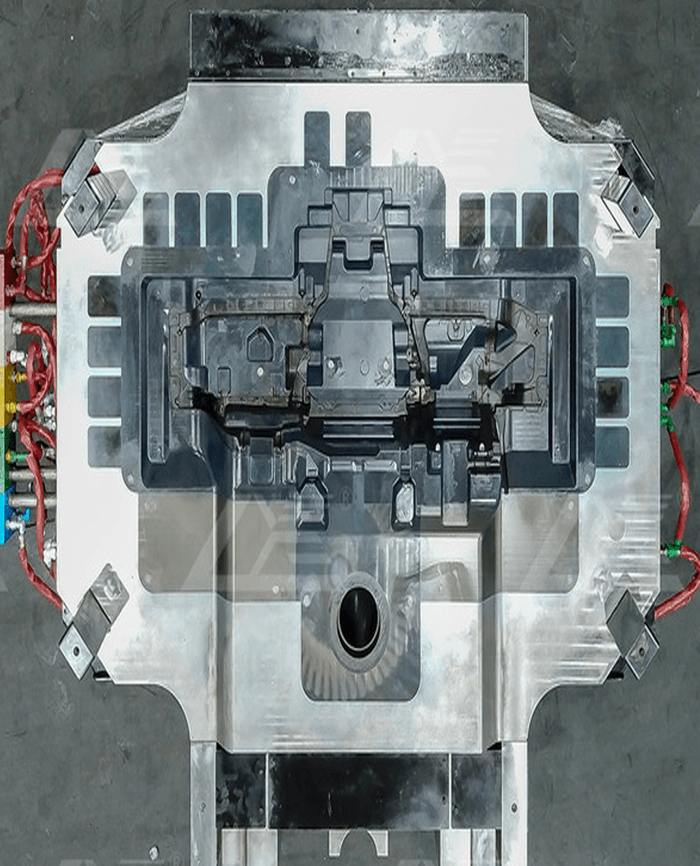

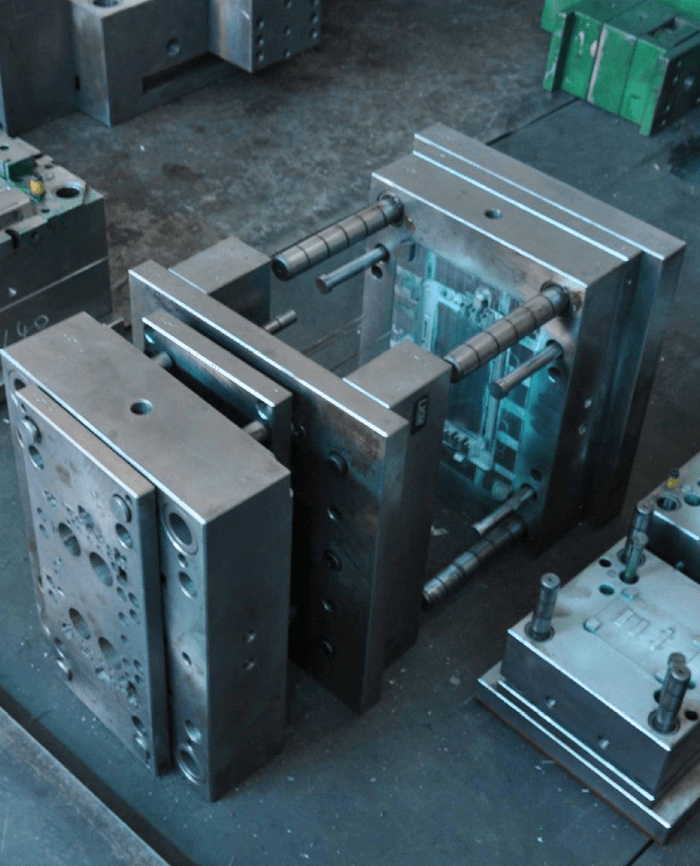

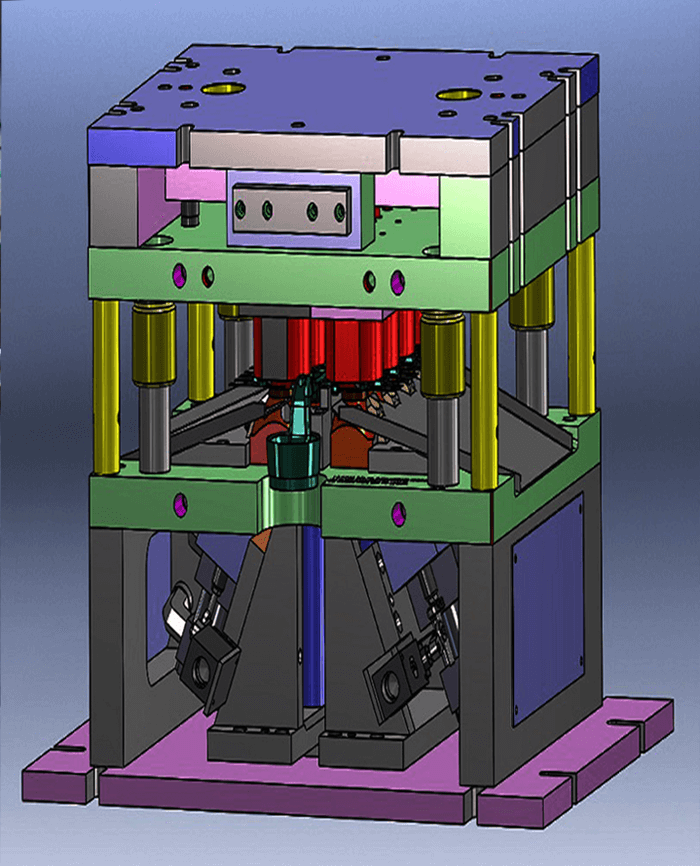

aCatTech( AT INDUSTRIAL ) is located at Dongguan City, Guangdong Province. Professional designing and manufacturing die-casting Tools for zinc and aluminum alloy , Our factory can do the parts of zinc alloy and aluminum alloy and CNC parts processing , Since its establishment in 2004, Our company has accumulated management experience for many years and excellent management team, which can provide quality service for all customer.

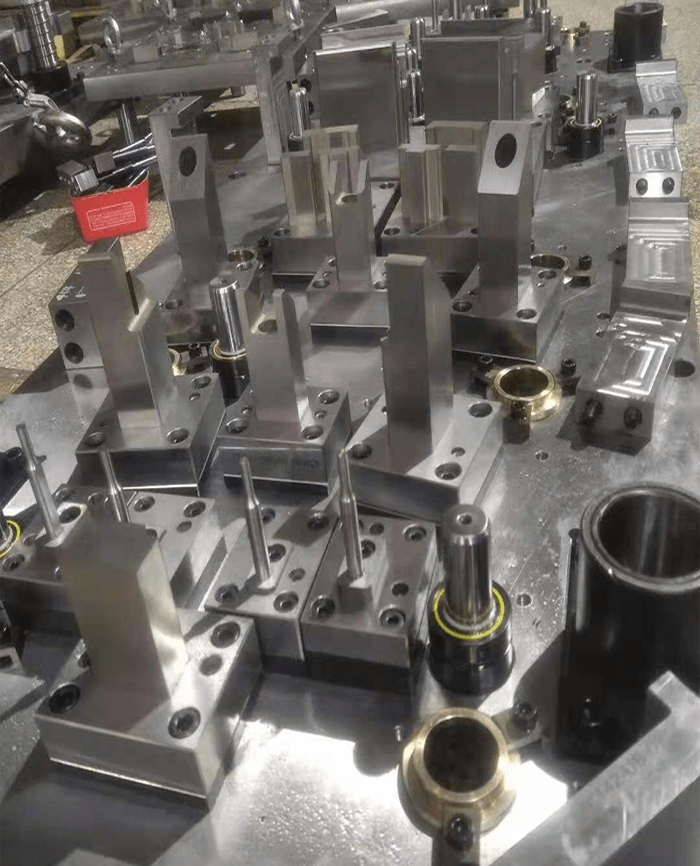

Our company covers an area of 20,000 square meters and plant area of 12,000 square meters. The production department had hot chamber die casting machine, cold chamber die casting machine and CNC machine, EDM machine, milling machine, Grinding Machine, wire cutting, ultrasonic cleaning machine.Testing equipment: Projector, CMM .The company has successfully passed ISO9001 and IATF 16949 certification.

Quality assurance: our factory has mature technical force, supporting professional equipment, perfect testing instruments and effective quality system.

Die-casting tools and parts mainly in: auto parts, machine parts, Accessories for communication equipment ,medical accessories and Electronic parts

Company tenet : Quality first, Quick response, Customer satisfaction, quality service

Have mold development and production capacity, mold design and production team, and independent mold making workshop; Better control mold precision, product quality and production progress.

There are 10 88T-160T zinc alloy die casting machines. Each

machine is equipped with automatic sprayer and pick up parts, with a central melting furnace to ensure product quality and reduce sand hole rate.

List of aluminum alloy die casting machine

160t 2 sets, 280t 5 sets, 400t 2 sets, 500t 1 set, 800t 1 set, 1000t 1 set, 1250t 1 set, 2000t 1 set

More about us, please contact us. We are a High Pressure Die-casting Solution One Station Manufacture.