Heat Checking in High-Pressure Die Casting Molds

Formation Mechanism and Pre-emptive Prevention of Heat Checking in High-Pressure Die Casting Molds

Heat checking is another common and severe issue in high-pressure die casting molds. Through long-term production and research, aCatTech has developed a deep understanding of its formation mechanism and prevention measures.

Three-Stage Model of Heat Checking Development and Key Triggers

- Crack Initiation Stage (Stage I)

In this stage, non-metallic inclusions at grain boundaries (e.g., sulfides, oxides) cause stress concentration, triggering microcracks (size < 50μm) under thermal cycles (temperature difference > 300℃). We have observed that carbide segregation or aggregation reduces grain boundary bonding strength, forming initial crack sources—this is frequently noted during mold inspection and analysis.

- Crack Propagation Stage (Stage II)

Untreated microcracks, under the impact of high-pressure (> 100MPa) molten metal, connect along grain boundaries or interdendritic regions to form visible heat checking (width 0.1-0.5mm). Meanwhile, high-temperature softening of die steel (hardness reduction > 15% at > 500℃) accelerates lateral crack propagation, posing a significant threat to mold lifespan.

- Structural Failure Stage (Stage III)

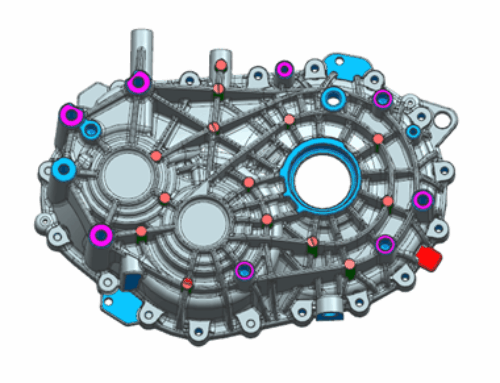

When the heat checking network penetrates, local strength loss occurs, leading to mold collapse or penetration. Our statistical data shows that typical failure locations concentrate in thermal stress concentration areas such as near gates and around cooling water channels.

Construction of Full-Cycle Prevention System

- Material Performance Enhancement

We select high-purity die steels (purity grade ≥ A0.5) and strengthen grain boundaries by adding zirconium and boron (0.01%-0.05% content). Vacuum heat treatment is adopted to eliminate internal pores and structural defects, improving the mold’s thermal fatigue resistance—this is a key measure in our material selection and processing.

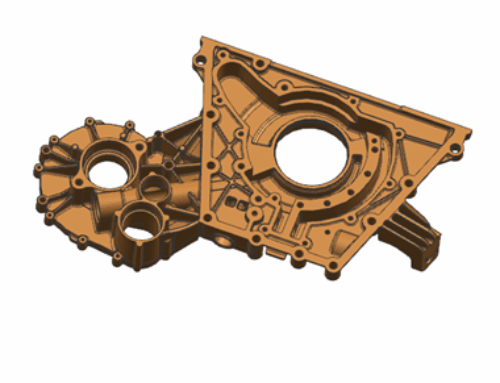

- Design and Structural Optimization

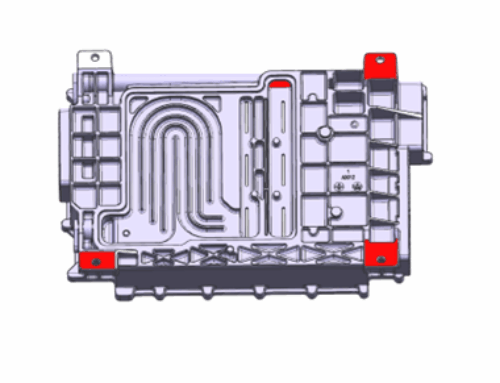

In design, we avoid sharp angles (minimum R angle ≥ 3mm) and use hyperbolic flow-guiding structures in critical transition areas to reduce stress concentration. Cooling water channels are maintained at 3-5 times the hole diameter from the cavity surface to avoid local overheating. For heat checking-prone areas (e.g., parting surfaces, core roots), stress relief grooves are added—an effective design method verified through repeated practice.

- Usage and Maintenance Strategies

We have established strict mold preheating curves: heating rate ≤ 10℃/min with 2-hour insulation to avoid sudden temperature changes. Stress relief annealing (520℃ × 4 hours) is performed every 5,000 cycles to eliminate accumulated thermal stress. Cavity surfaces are inspected regularly (weekly) using fluorescent testing to detect early cracks, enabling early detection and treatment.

Emergency Treatment Technologies and Lifespan Restoration Solutions for Scuffing and Heat Checking

Timely and effective treatment is crucial when molds develop scuffing or heat checking. aCatTech has accumulated rich experience in emergency treatment and restoration.

(I) Rapid Repair Strategies for Scuffing Issues

- Minor Scuffing (Depth < 0.2mm)

For minor scuffing, we use diamond grinding heads to refine damaged areas, paired with 1000# and finer sandpaper for polishing, restoring surface roughness to Ra ≤ 0.8μm. Meanwhile, local application of molybdenum disulfide coating (5-10μm thickness) enhances anti-adhesion performance. Such treatment typically restores normal mold functionality.

- Moderate Scuffing (Depth 0.2-0.5mm)

For moderate scuffing, EDM deposition repair is adopted using H13 welding wires. After repair, local quenching (induction heating to 950℃) + low-temperature tempering (200℃) is performed to restore hardness to HRC 46-48. After grinding, draft angle compensation (1°-2° increase) is applied to reduce re-scuffing risks.

- Severe Scuffing (Depth > 0.5mm or Large-Area Damage)

For severe scuffing, if the mold has removable inserts, we replace them using shrink fitting (interference 0.02-0.05mm) to ensure positioning accuracy. If insert replacement is impossible, the entire cavity is ground (removal ≥ 1mm) and re-nitrided (case depth 0.3-0.5mm) to maximize mold performance restoration.

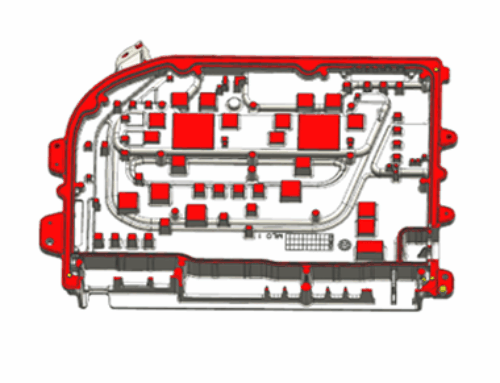

Graded Repair Technologies for Heat Checking Defects

- Early Heat Checking (Crack Length < 10mm, Depth < 0.3mm)

For early heat checking, laser cladding technology (power 1.5-2.0kW) is used, with cladding layer composition matching the die steel. After cooling, ultra-precision grinding is performed. Post-repair low-temperature tempering (180℃ × 2 hours) eliminates laser processing stress, ensuring good mold lifespan after repair.

- Mid-Stage Heat Checking (Crack Length 10-50mm, Depth 0.3-1.0mm)

For mid-stage heat checking, the cracked area is milled out (2mm expansion), and EDM build-up welding is applied (layered welding, each layer ≤ 0.5mm thickness). Post-welding high-temperature tempering (560℃ × 3 hours) is conducted. Coordinate grinding machines refine the profile with precision controlled within ±0.01mm to ensure mold accuracy.

- Deep Heat Checking Repair and Lifespan Extension

For deep heat checking, the entire mold undergoes secondary quenching (heating rate 5℃/min, holding time calculated by thickness) with high-pressure gas quenching. PVD coating (TiN/TiCN, 3-5μm thickness) is applied to enhance thermal fatigue and erosion resistance. After repair, a dedicated usage plan is formulated, limiting cycles ≤ 20,000 with enhanced monitoring to ensure production safety.

Post-Repair Performance Verification and Continuous Monitoring

- Quality Inspection

After repair, 3D scanners (precision ±0.02mm) are used to inspect profile dimensions, ensuring draft angles and roughness meet design requirements. Hardness testers (10kg load) sample repair areas, with hardness deviation ≤ ±2HRC to guarantee repair quality.

- Production Verification

First-piece production involves continuous test runs of 50 cycles, observing casting surface quality (scuffing grade ≤ 1, no new heat checking). Mold temperature and injection pressure data are collected every 200 cycles, and a thermal stress early warning model for crack-sensitive areas is established (threshold ≥ 80MPa) to detect potential issues promptly.

Recommendations for Customers

- In the early stage of mold design, we recommend full communication with aCatTech. We will provide professional mold design solutions based on your product characteristics and production needs, reducing scuffing and heat checking risks from the source.

- Select high-quality mold materials and strictly follow our material standards for procurement and inspection to ensure material performance meets requirements.

- During production, strictly adhere to our formulated process parameters and maintenance strategies. Regularly inspect and maintain molds to detect and address potential issues promptly.

- When molds develop scuffing, heat checking, or other issues, we recommend contacting us promptly. Based on the mold damage, we will provide professional repair solutions to maximize mold lifespan and reduce production costs.

Through the above full-process technical solutions from prevention to remediation, aCatTech is committed to providing systematic solutions for high-pressure die casting molds in the automotive sector. While controlling defect risks at the source, we maximize mold lifespan through efficient repair technologies, helping customers achieve both quality and efficiency improvements.